China Wholesale Api Valve Balls And Valve Seats Factory – Tungsten Carbide Inlet Plate – N&D

Short Description:

China Wholesale Api Valve Balls And Valve Seats Factory – Tungsten Carbide Inlet Plate – N&D Detail:

Tungsten carbide hard alloy are specifically designed to resist corrosion, abrasion, wear, fretting, sliding wear and impact both onshore and offshore and surface and sub-sea equipment applications.

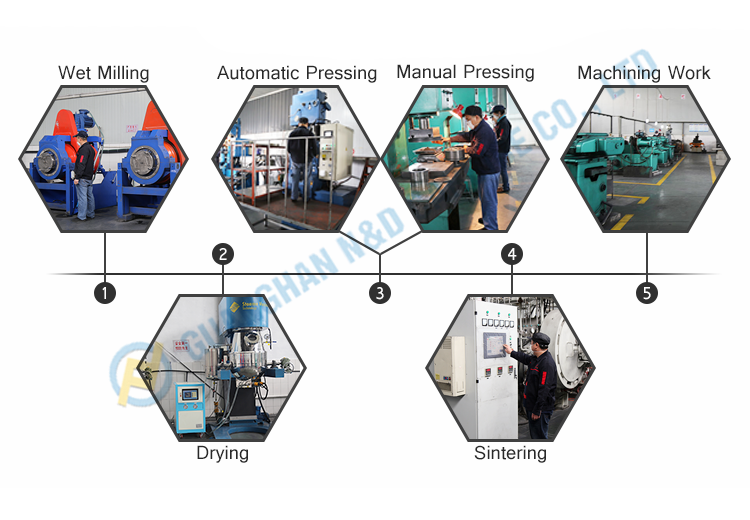

Tungsten carbide is an inorganic chemical compound which contains numbers of tungsten and carbon atoms. Tungsten carbide, also known as “cemented carbide”, “hard alloy” or “hardmetal”, is a kind of metallurgic material which contains tungsten carbide powder (chemical formula: WC) and other binder (cobalt, nickel. etc.).It can be pressed and formed into customized shapes, can be grinded with precision, and can be welded with or grafted to other metals. Various types and grades of carbide can be designed as required for use in application intended, including chemical industry, oil & gas and marine as mining and cutting tools, mould and die, wear parts, etc

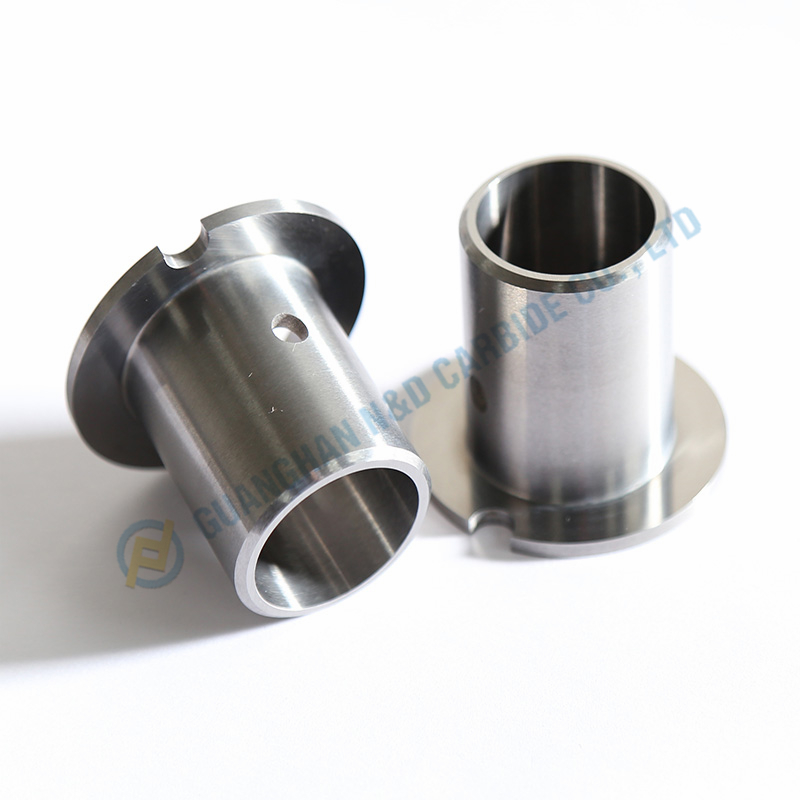

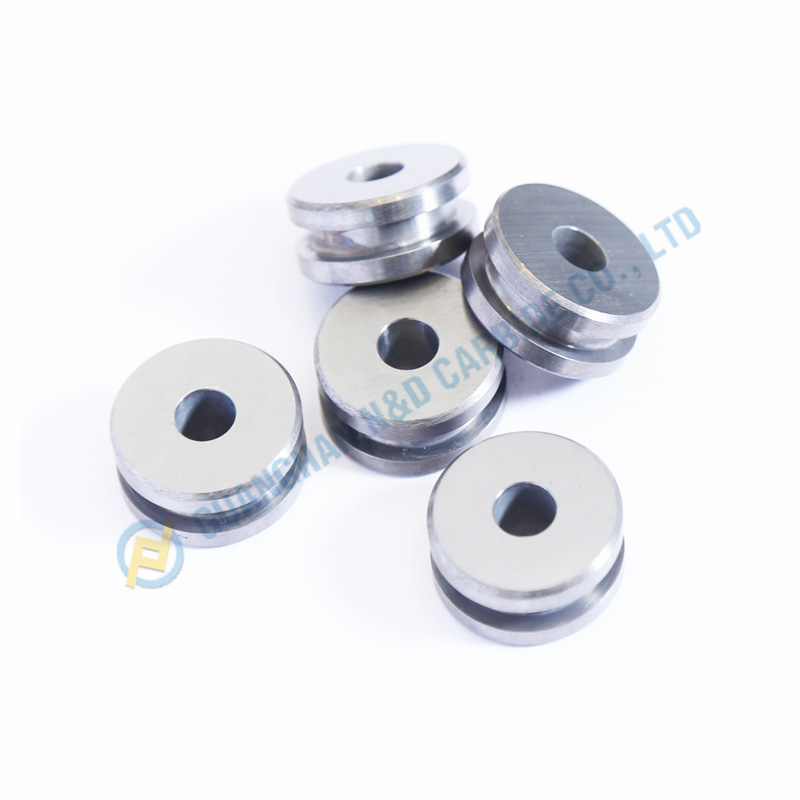

Tungsten carbide inlet plate are widely used for pulser motion of WMD&LWD system.

Tungsten carbide for drilling MWD/LWD includes two types:Both the main body and the threaded part are made of tungsten carbide,which is called the overall hard alloy main valve head;The main body is tungsten carbide and the threader part is made of stainless steel(such as stainless steel 304,etc) which is called a welded main valve head.

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future jointly with your esteemed company for China Wholesale Api Valve Balls And Valve Seats Factory – Tungsten Carbide Inlet Plate – N&D, The product will supply to all over the world, such as: Guatemala, Burundi, Monaco, If you are for any reason unsure which product to select, do not hesitate to contact us and we are going to be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We have been looking for more and more customers to create the glorious future.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.