China Wholesale Carbide Balls And Valve Seat Suppliers – Tungsten Carbide Wear Rings for Oil and Gas Industry – N&D

Short Description:

China Wholesale Carbide Balls And Valve Seat Suppliers – Tungsten Carbide Wear Rings for Oil and Gas Industry – N&D Detail:

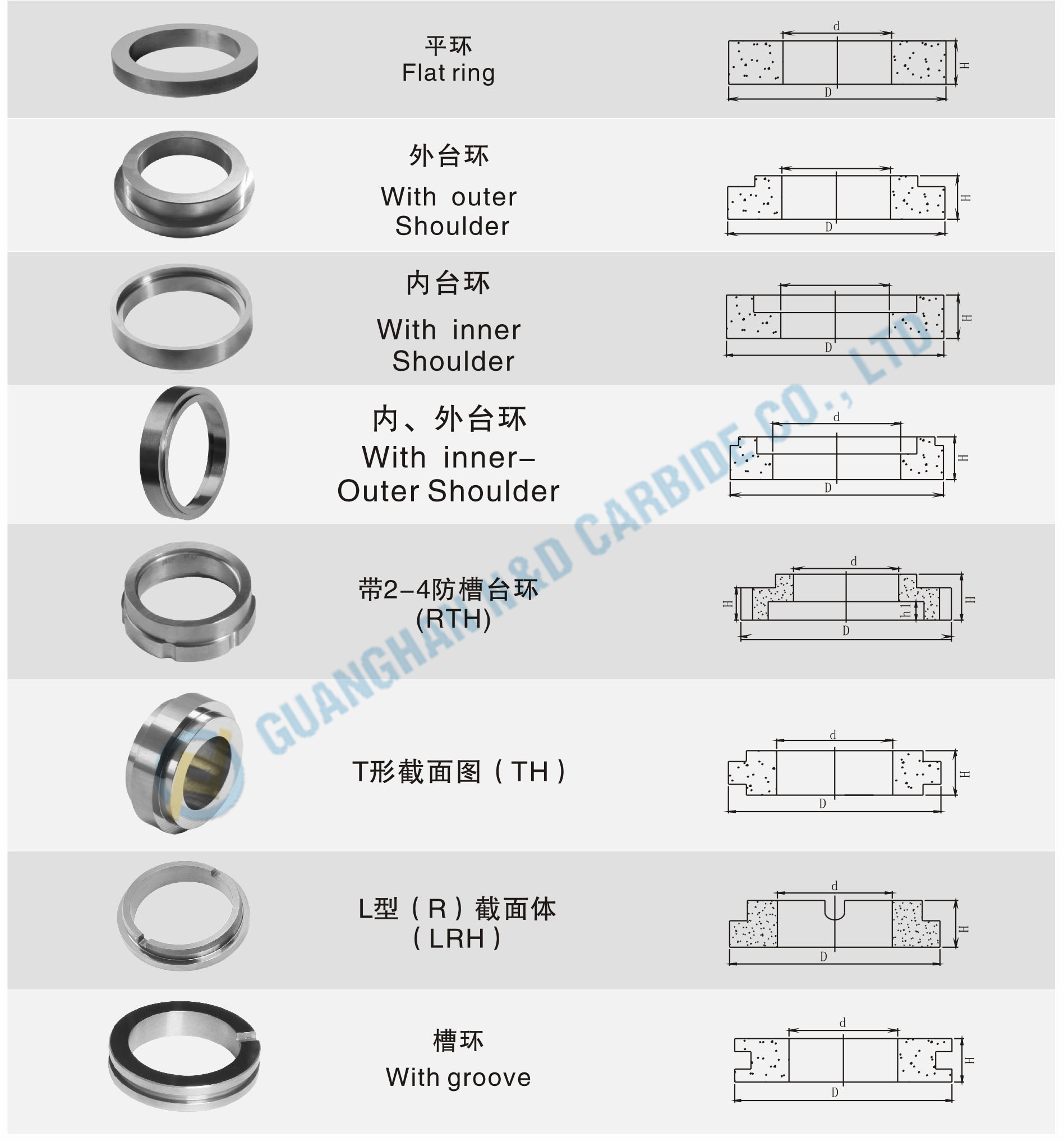

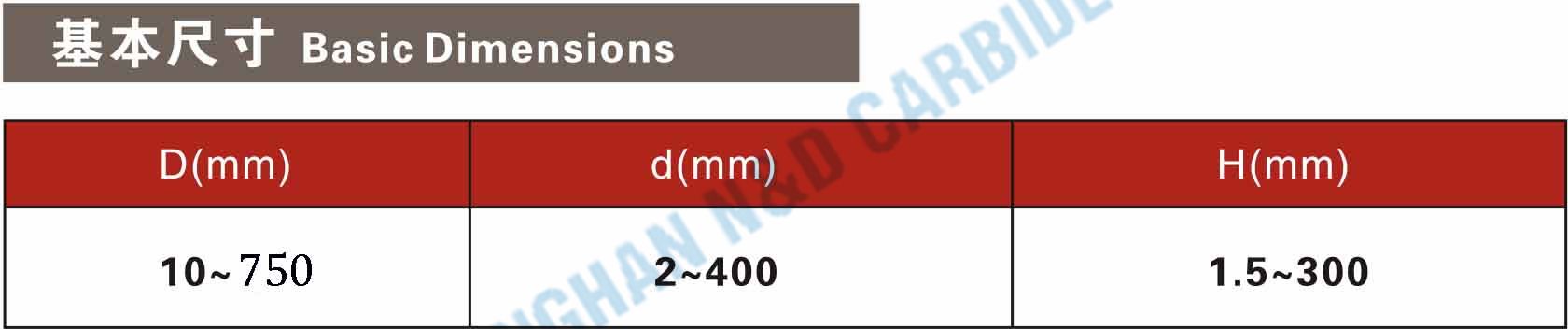

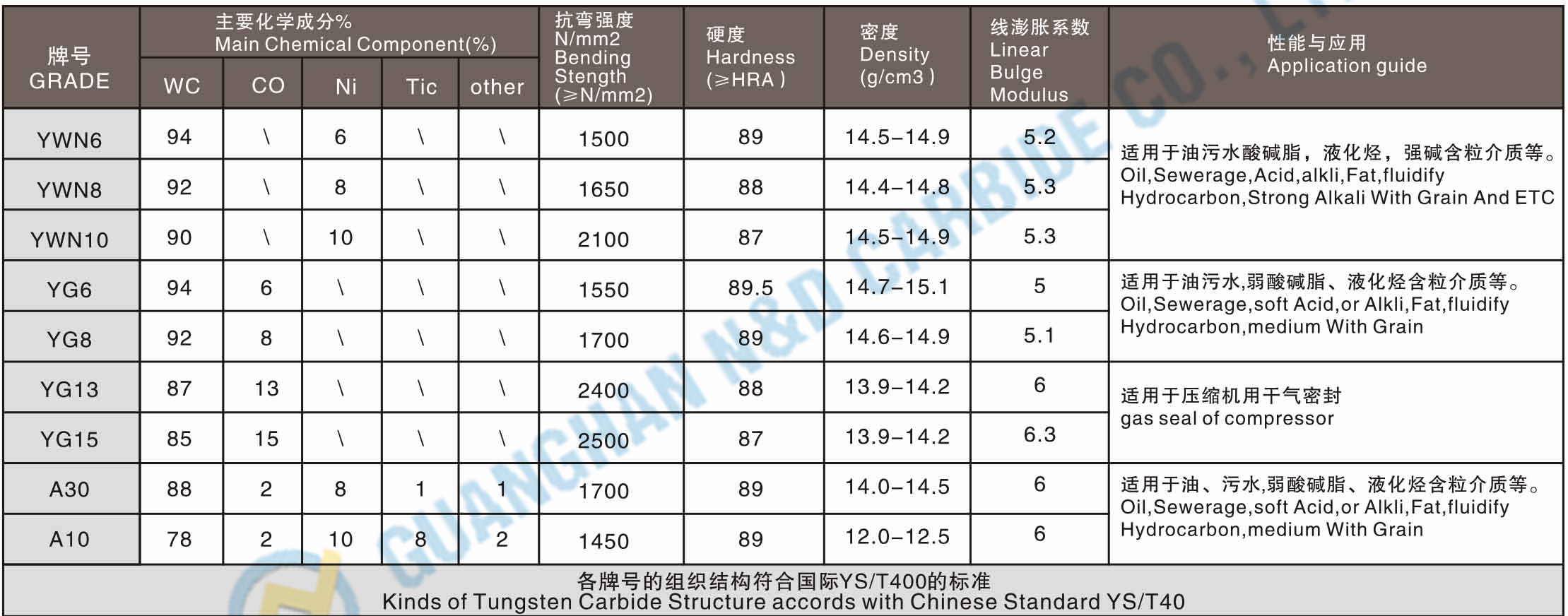

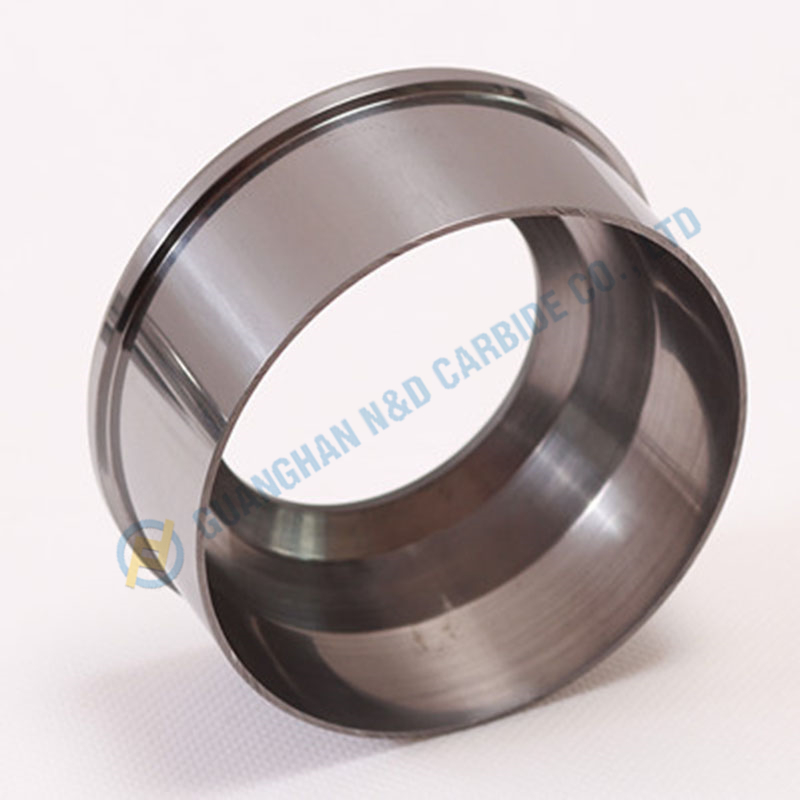

Tungsten carbide(TC) is widely used as seal faces or rings with resistant-wearing,high fractural strength,high thermal conductivity, small heat expansion co-efficient.The two most common variations of tungsten carbide seal faces/ring are cobalt binder and nickel binder.

Tungsten carbide hard alloy are specifically designed to resist corrosion, abrasion, wear, fretting, sliding wear and impact both onshore and offshore and surface and sub-sea equipment applications.

Tungsten Carbide wear rings are widely used as seal faces in mechanical seals for pumps, compressors mixers and agitators found in oil refineries, petrochemical plants, fertilizer plants, breweries, mining , pulp mills, and the pharmaceutical industry. The seal-ring will be installed on the pump body and rotating axle, and forms through the end face of the rotating and static ring a liquid or gas seal.

Product detail pictures:

Related Product Guide:

We provide good power in high-quality and progress,merchandising,revenue and internet marketing and operation for China Wholesale Carbide Balls And Valve Seat Suppliers – Tungsten Carbide Wear Rings for Oil and Gas Industry – N&D, The product will supply to all over the world, such as: Philadelphia, Uganda, Egypt, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We've been looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to deliver you with high quality and efficient services.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.