China Wholesale Tungsten Carbide Shaft Sleeve Bush Manufacturers – Tungsten Carbide Bearing Bush – N&D

Short Description:

China Wholesale Tungsten Carbide Shaft Sleeve Bush Manufacturers – Tungsten Carbide Bearing Bush – N&D Detail:

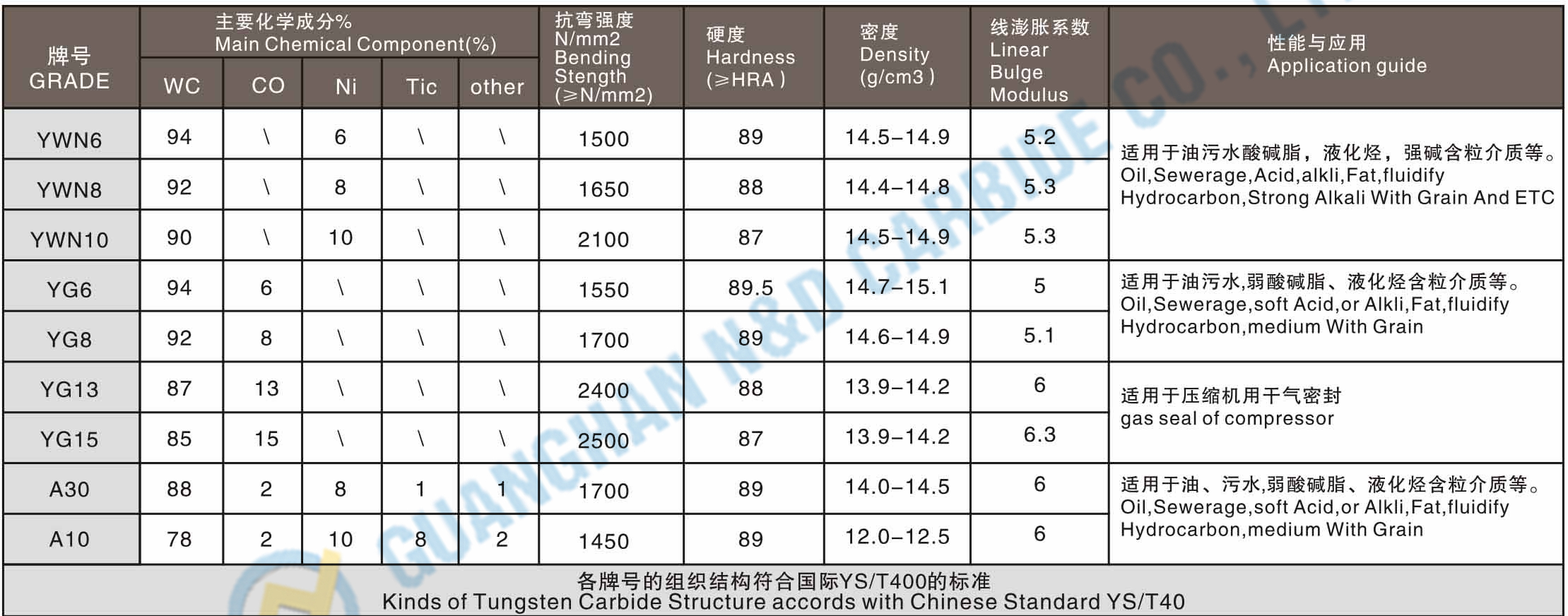

Tungsten carbide is an inorganic chemical compound which contains numbers of tungsten and carbon atoms. Tungsten carbide, also known as “cemented carbide”, “hard alloy” or “hardmetal”, is a kind of metallurgic material which contains tungsten carbide powder (chemical formula: WC) and other binder (cobalt, nickel. etc.).

Tungsten carbide bearing bush shows high hardness and transverse rupture strength, and it has superior performance on resisting abrasion and corrosion, which enable it to be widely used in many industries.

The tungsten carbide bearing bush sleeve will be used mainly for rotating support, aligning, anti-thrust and seal of the axle of motor, centrifuge, protector and separator of the submerged electric pump in the adverse working conditions of high speed rotating, sand lash abrasion and gas corrosion in the oil field, such as slide bearing sleeve, motor axle sleeve and seal axle sleeve.

Cemented carbide sleeve adopts raw and auxiliary materials such as primary saturated tungsten carbide, high-purity ultra-fine cobalt powder, precise carbon blending, tilt ball milling, vacuum stirring drying, precision pressing, digital degreasing sintering and pressure sintering personalized post-processing and other advanced powder metallurgy processes. Hard alloy sleeve is widely used in special pump industry, with long service life and reliable quality.

Bearing bush sleeves are working in an abrasive environment due to rotation, friction, etc. and the particles involved in the media.

Tungsten carbide bushing sleeve with wear and corrosion resistance and a high fracture toughness for demanding axial thrust, and could meet API standard disaster bushing requirement.

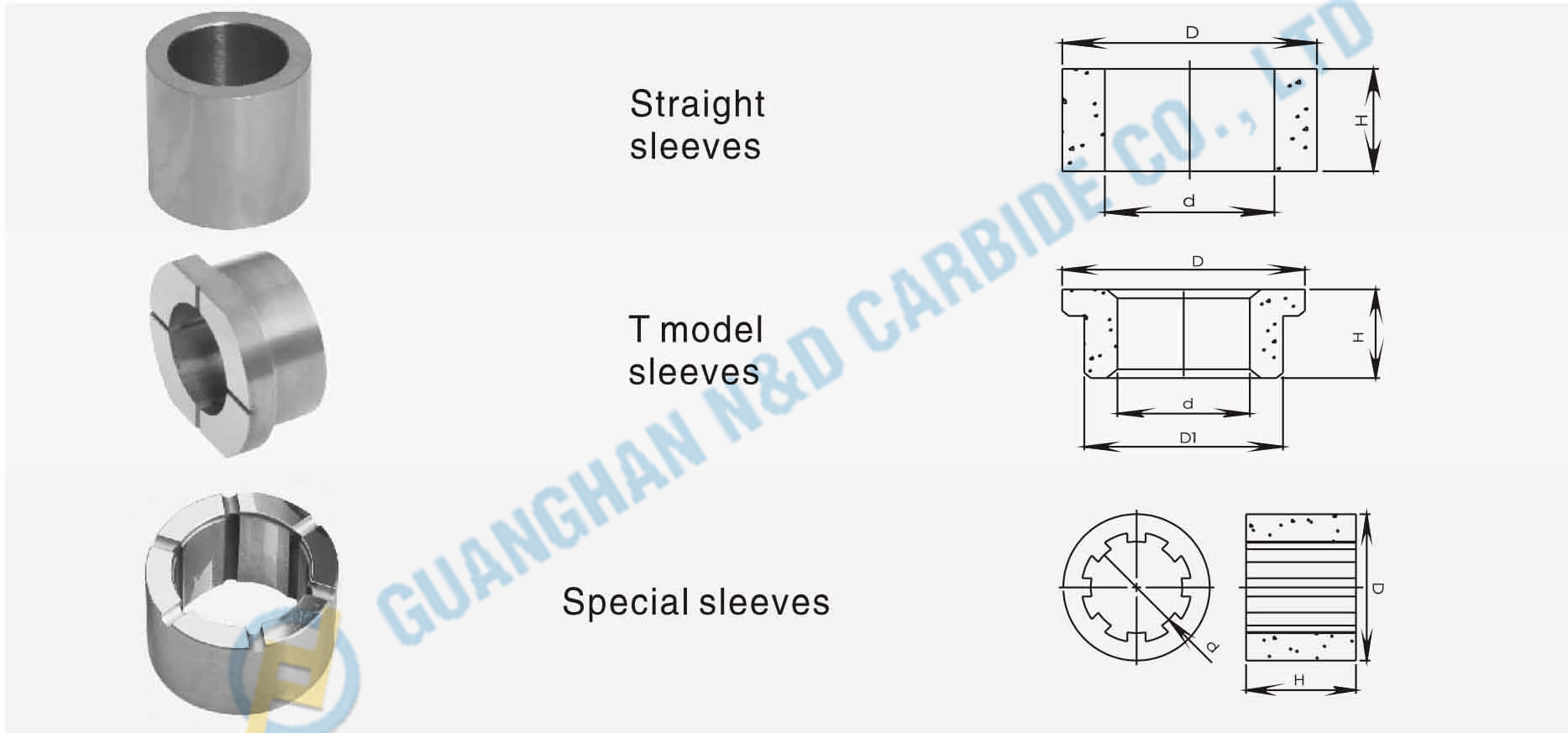

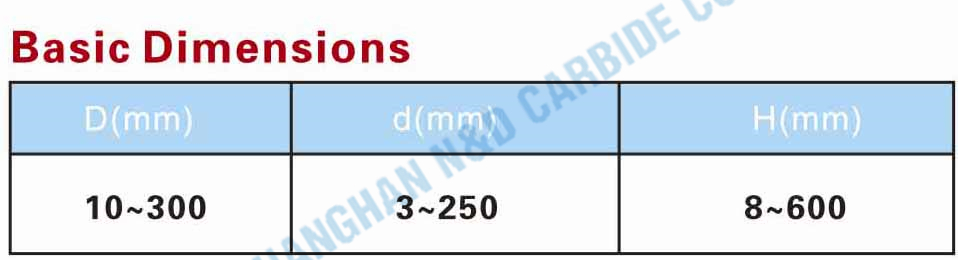

There is a big choice of sizes and types of the tungsten carbide bush sleeve, we can also recommend, design, develop, produce the products according to the drawings and requirements of the customers.

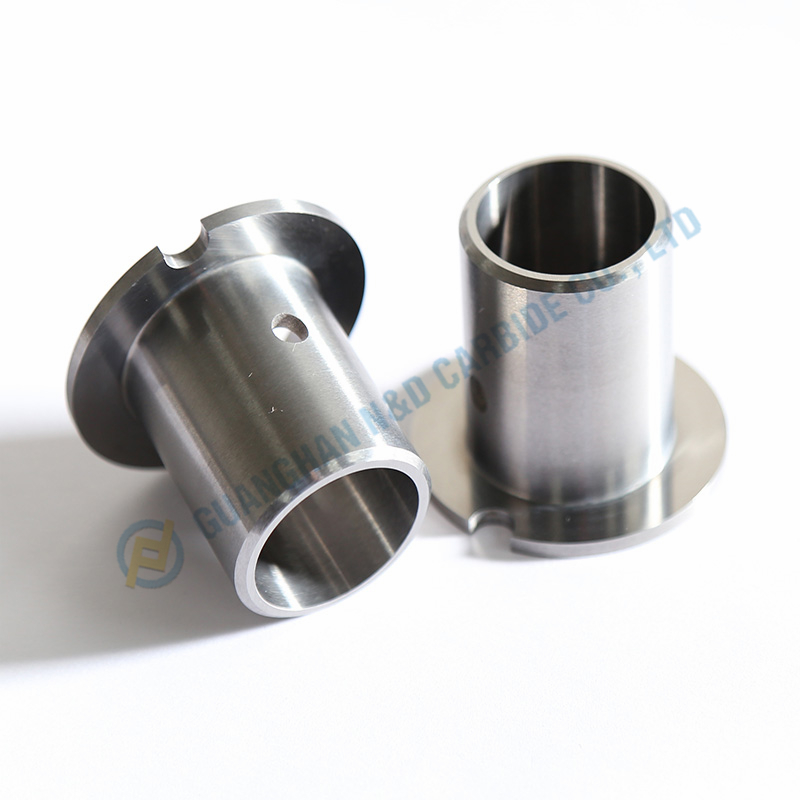

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of China Wholesale Tungsten Carbide Shaft Sleeve Bush Manufacturers – Tungsten Carbide Bearing Bush – N&D, The product will supply to all over the world, such as: Ukraine, Hamburg, St. Petersburg, Each product is carefully made, it will make you satisfied. Our products in the production process have got strictly monitored, because it is only to provide you the best quality, we will feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.