Custom Tungsten Carbide Seal Ring for Mechanical Seals

Short Description:

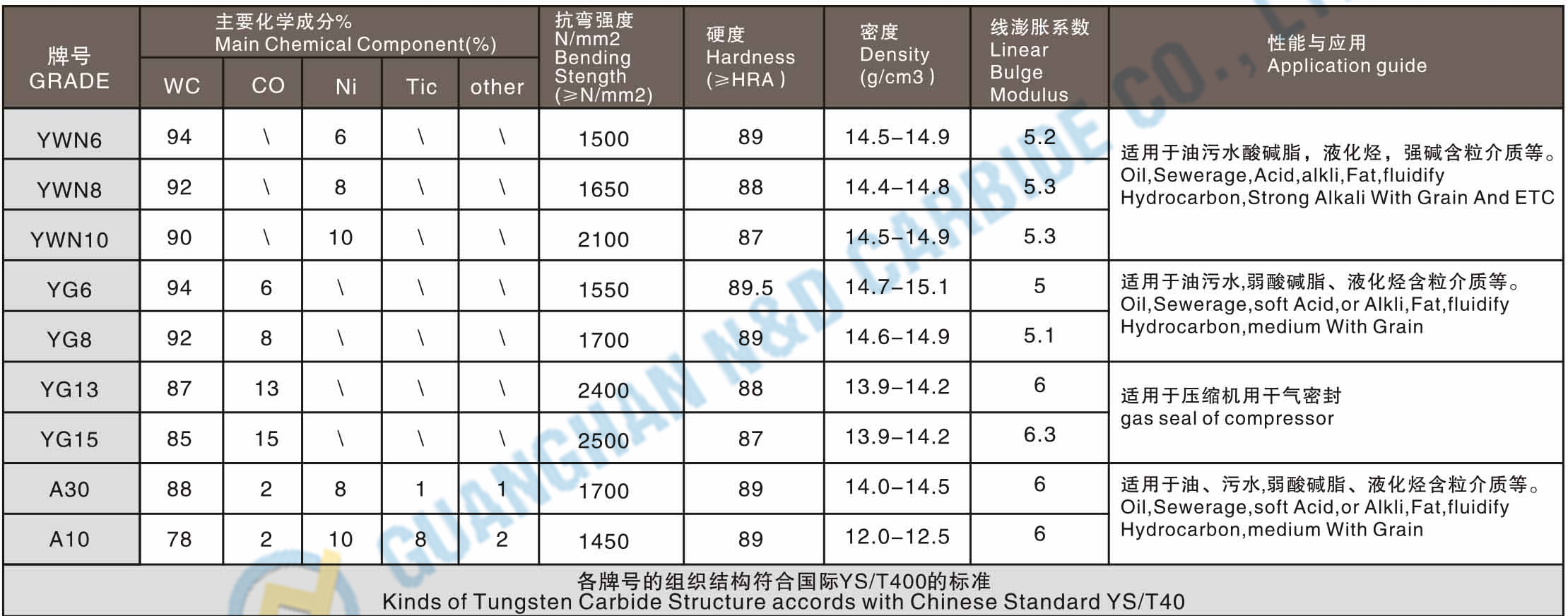

* Tungsten Carbide, Nickel/Cobalt Binder

* Sinter-HIP Furnaces

* CNC Machining

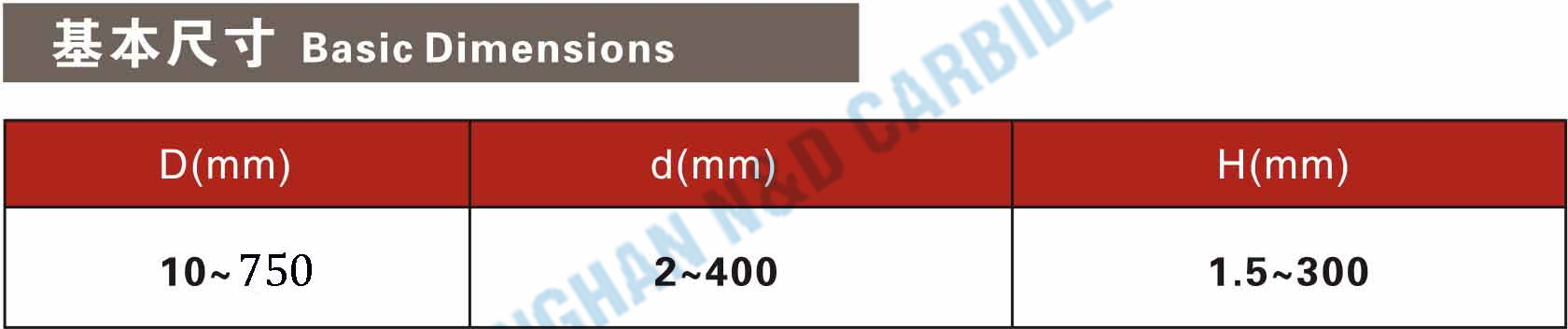

* Outer Diameter: 10-800mm

* Sintered, finished standard, and mirror lapping ;

* Additional sizes,tolerances, grades and quantities are available upon request.

Introducing our custom Tungsten Carbide Seal Ring for Mechanical Seals, the ultimate solution for ensuring optimal performance and longevity in mechanical seal applications. Crafted with precision and expertise, our seal rings are designed to withstand the most demanding industrial environments, offering exceptional wear resistance and reliability.

Our Tungsten Carbide Seal Rings are custom-made to meet the specific requirements of mechanical seals, ensuring a perfect fit and seamless integration. The superior hardness and toughness of tungsten carbide make it an ideal material for seal rings, providing excellent resistance to abrasion, corrosion, and high temperatures. This means that our seal rings can effectively prevent leakage and maintain a tight seal even in the most challenging conditions, ultimately reducing maintenance costs and downtime.

With our commitment to quality and innovation, we utilize advanced manufacturing techniques to produce seal rings that exceed industry standards. Each ring is meticulously inspected to guarantee precision and consistency, ensuring that our customers receive a product of the highest caliber.

In addition to their exceptional performance, our custom Tungsten Carbide Seal Rings are also highly customizable, allowing for tailored solutions to meet specific application needs. Whether it’s a unique size, shape, or special coating requirements, we have the capability to deliver bespoke seal rings that perfectly align with our customers’ specifications.

Furthermore, our dedication to customer satisfaction extends beyond the product itself. We provide comprehensive support and technical expertise to assist our customers in selecting the most suitable seal ring for their applications, as well as offering guidance on installation and maintenance best practices.

In conclusion, our custom Tungsten Carbide Seal Rings for Mechanical Seals offer unparalleled durability, reliability, and customization options, making them the ideal choice for industries where dependable sealing solutions are paramount. Trust in our expertise and experience to deliver seal rings that consistently outperform expectations and contribute to the seamless operation of mechanical systems.

Tungsten carbide(TC) is widely used as seal faces or rings with resistant-wearing,high fractural strength,high thermal conductivity, small heat expansion co-efficient.The tungsten carbide seal-ring can be divided into both of rotating seal-ring and static seal-ring.The two most common variations of tungsten carbide seal faces/ring are cobalt binder and nickel binder.

Tungsten carbide mechanical seals are being used increasingly on fluid pump to replace packed gland and lip seal. tungsten carbide mechanical seal Pump with mechanical seal perform more efficiently and generally perform more reliably for extended periods of time.

According to the shape, those seals are also called tungsten carbide mechanical seal rings. Due to the superiorities of tungsten carbide material, tungsten carbide mechanical seal rings shows high hardness, and the most important is that they resist corrosion and abrasion well. therefore, tungsten carbide mechanical seal rings are having wider use than seals of other materials.

Tungsten carbide mechanical seal is provided to prevent pumped fluid from leaking out along the drive shaft. The controlled leakage path is between two flat surfaces associated with the rotating shaft and the housing respectively. The leakage path gap varies as the faces are subjected to varying external load which tend to move the faces relative to each other.

The products require a different shaft housing design arrangement compared to that for the other type of mechanical seal because the mechanical seal is a more complicated arrangement and mechanical seal does not provide any support to the shaft.

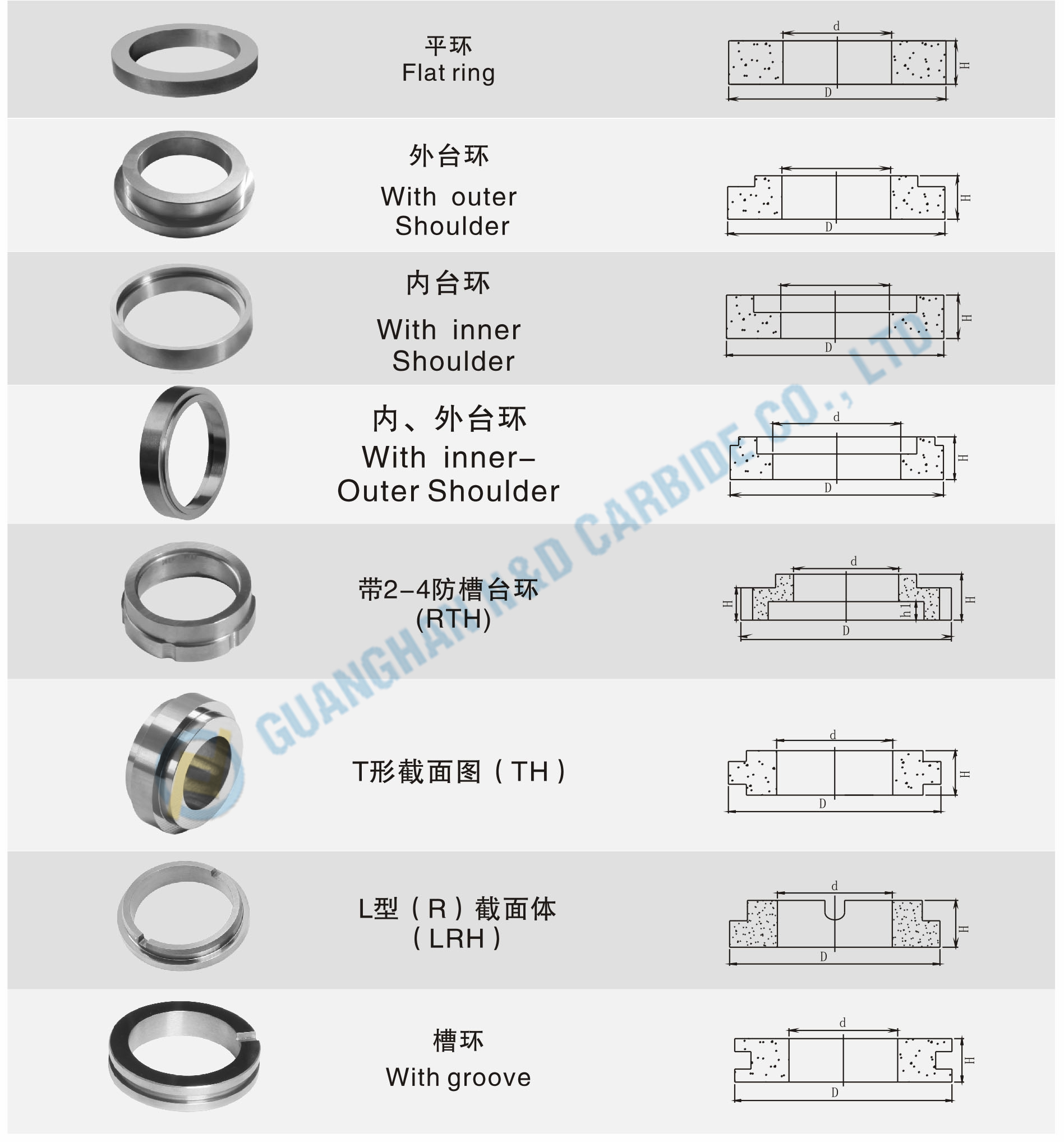

Tungsten carbide mechanical seal rings come in two primary types:

Cobalt bound (Ammonia applications should be avoided)

Nickel bound (May be used in Ammonia)

Typically 6% binder materials are used in tungsten carbide mechanical seal rings, although a wide range is available. Nickel-bonded tungsten carbide mechanical seal rings are more prevalent in the wastewater pump market due to their improved corrosion resistance compared with cobalt bound materials.

Tungsten Carbide seal rings are widely used as seal faces in mechanical seals for pumps, compressors mixers and agitators found in oil refineries, petrochemical plants, fertilizer plants, breweries, mining , pulp mills, and the pharmaceutical industry. The seal-ring will be installed on the pump body and rotating axle, and forms through the end face of the rotating and static ring a liquid or gas seal.

Tungsten carbide sealing rings, as an alloy product manufactured through powder metallurgy processes, boast a wide and vital range of applications. Below is a detailed elaboration on their application scope:

- Oil Extraction and Chemical Industries

In the oil extraction and chemical industries, carbide sealing rings are highly favored for their remarkable wear resistance, corrosion resistance, and impact resistance. These properties enable them to operate stably over extended periods in harsh working environments, effectively preventing medium leakage and ensuring production safety. Carbide sealing rings are commonly used as critical sealing components in various pumps, compressors, valves, and other equipment. - Machinery Manufacturing Sector

Carbide sealing rings also play a significant role in the machinery manufacturing sector. They are widely applied in oil cylinder guides, various manufacturing machinery, and automated mechanical equipment, such as seals for telescopic, oscillating, sliding, bending, and rotating components. The high hardness and wear resistance of carbide sealing rings significantly extend equipment lifespan, reduce maintenance and replacement frequencies, and lower operational costs for enterprises. - Transportation Industry

Carbide sealing rings occupy an important position in the transportation industry. They are present in automobiles, motorcycles, and various handling and agricultural machinery, where numerous sliding and rotating parts require reliable seals. The sealing performance of these components directly affects the safety and reliability of vehicles. Carbide sealing rings, with their exceptional sealing performance and wear resistance, provide a dependable safeguard for these components. - Instrumentation Industry

Carbide sealing rings also play a crucial role in the instrumentation industry. As instrumentation typically operates in precise and stable environments, the demands on sealing components are extremely high. Carbide sealing rings, with their high precision, corrosion resistance, and wear resistance, fulfill the stringent requirements of instrumentation for sealing components. - Other Fields

Furthermore, carbide sealing rings are widely used in various sectors such as power, metallurgy, and food processing. In the power industry, they are utilized for sealing equipment in power generation; in metallurgy, they are employed for sealing under high-temperature and high-pressure conditions; and in food processing, their corrosion resistance and hygienic properties make them essential components on food production lines.

In summary, carbide sealing rings, with their superior performance and extensive application range, play a pivotal role in modern industries. As technology continues to advance and applications continue to expand, the market prospects for carbide sealing rings will become even more promising."

There is a big choice of sizes and types of the tungsten carbide flat seal ring, we can also recommend, design, develop, produce the products according to the drawings and requirements of the customers.