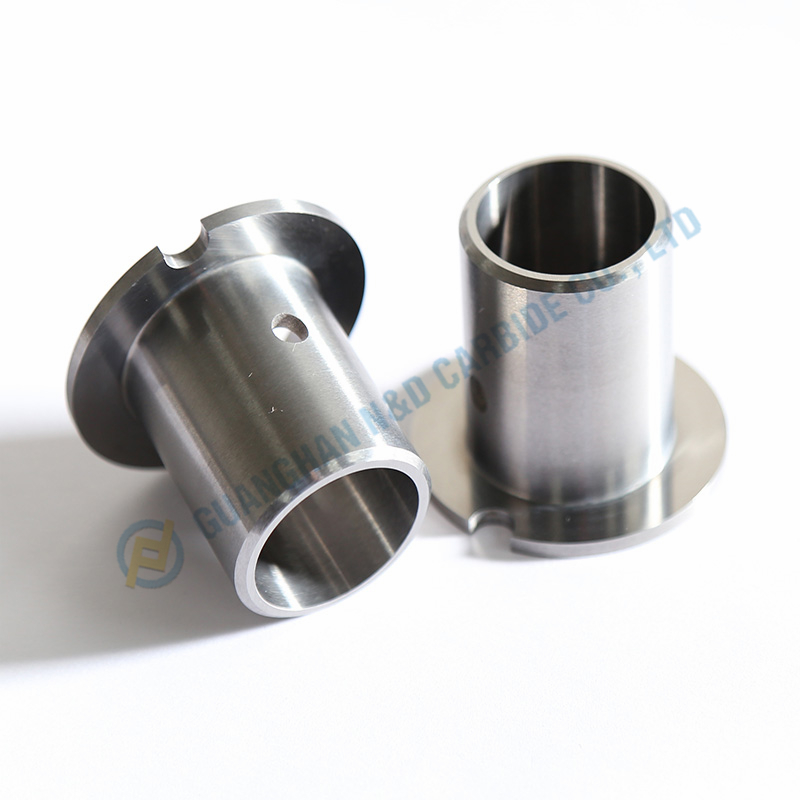

Tungsten Carbide Guide Bush

Short Description:

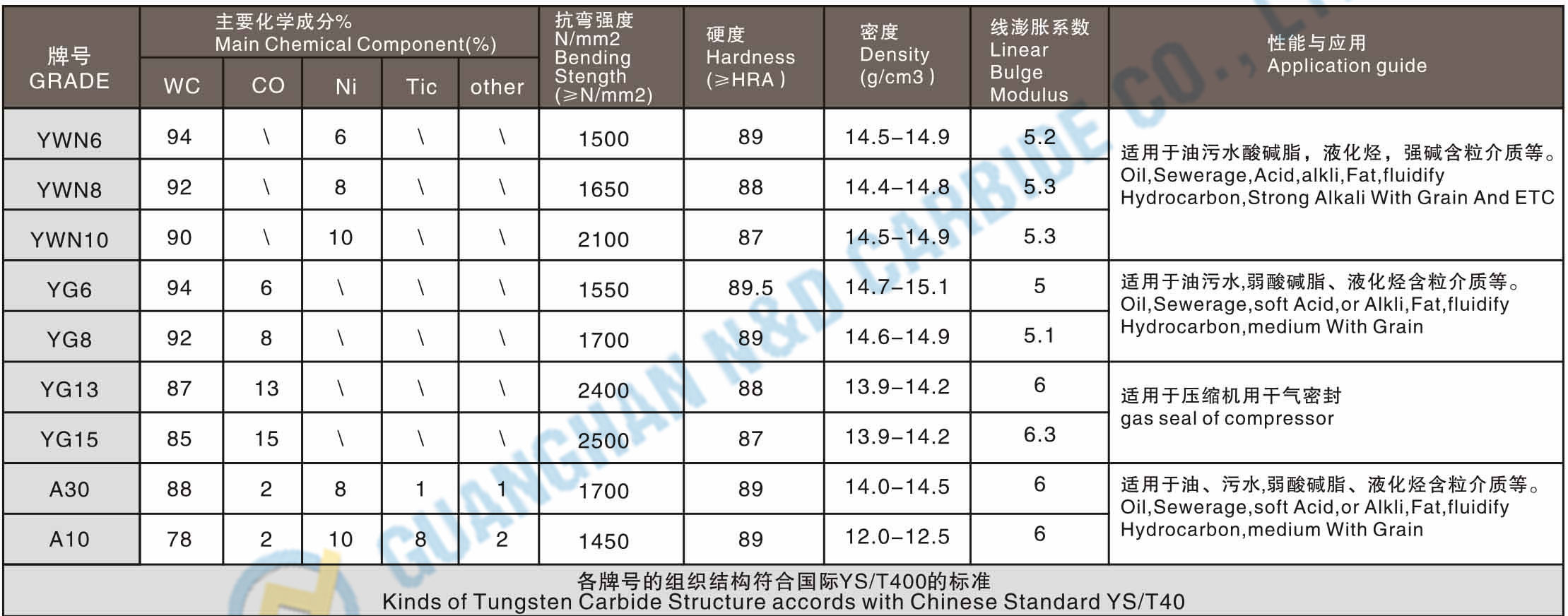

* Tungsten Carbide, Nickel/Cobalt Binder

* Sinter-HIP Furnaces

* CNC Machining

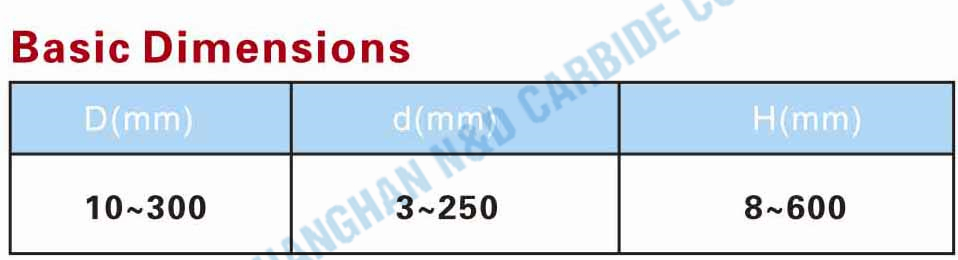

* Outer Diameter: 10-500mm

* Sintered, finished standard, and mirror lapping ;

* Additional sizes,tolerances, grades and quantities are available upon request.

Tungsten carbide is an inorganic chemical compound which contains numbers of tungsten and carbon atoms. Tungsten carbide, also known as “cemented carbide”, “hard alloy” or “hardmetal”, is a kind of metallurgic material which contains tungsten carbide powder (chemical formula: WC) and other binder (cobalt, nickel. etc.).

Tungsten carbide guide bush shows high hardness and transverse rupture strength, and it has superior performance on resisting abrasion and corrosion, which enable it to be widely used in many industries.

The tungsten carbide guide bush sleeve will be used mainly for rotating support, aligning, anti-thrust and seal of the axle of motor, centrifuge, protector and separator of the submerged electric pump in the adverse working conditions of high speed rotating, sand lash abrasion and gas corrosion in the oil field, such as slide bearing sleeve, motor axle sleeve and seal axle sleeve.

Tungsten carbide bush adopts raw and auxiliary materials such as primary saturated tungsten carbide, high-purity ultra-fine cobalt powder, precise carbon blending, tilt ball milling, vacuum stirring drying, precision pressing, digital degreasing sintering and pressure sintering personalized post-processing and other advanced powder metallurgy processes. Hard alloy sleeve is widely used in special valve industry, with long service life and reliable quality.

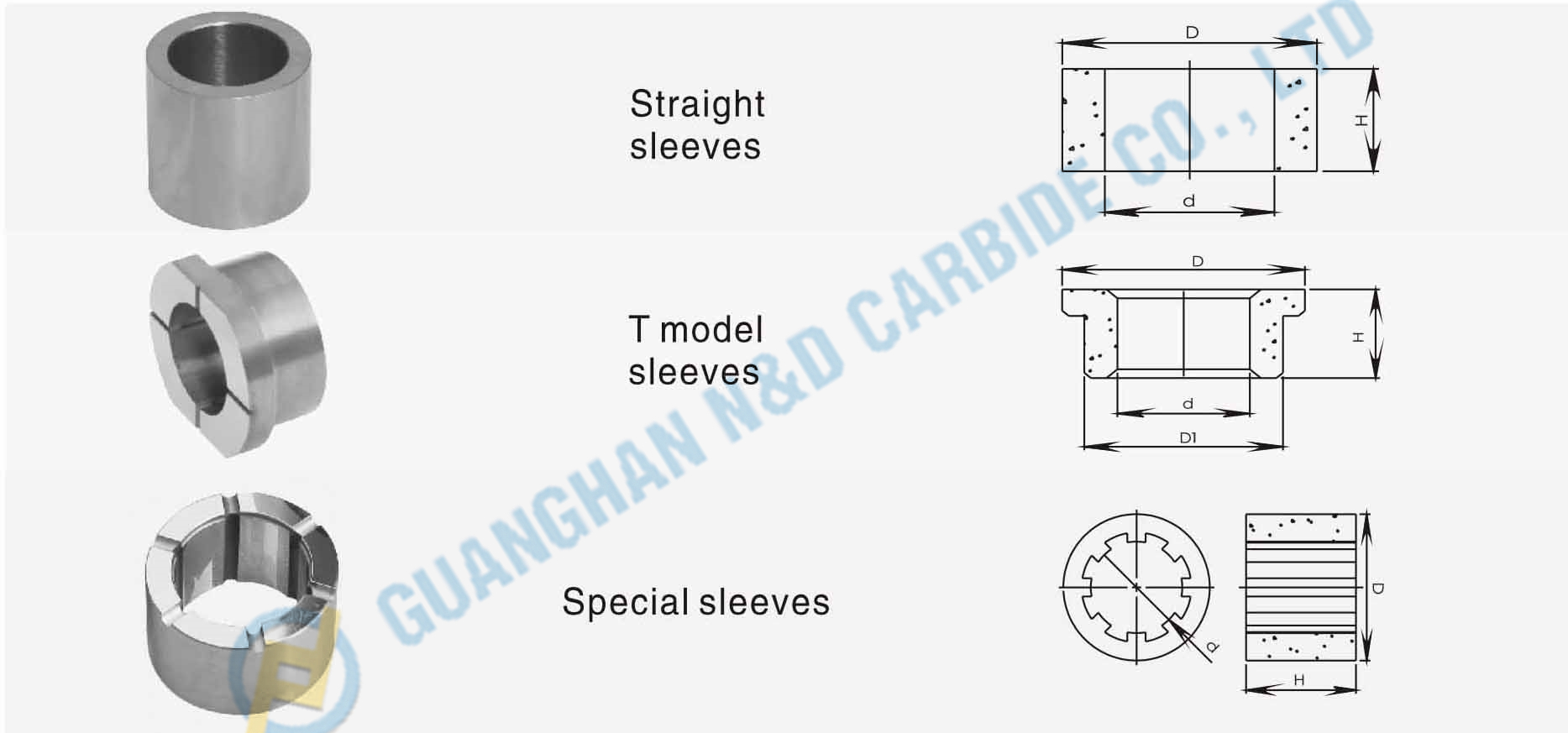

There is a big choice of sizes and types of the tungsten carbide bush sleeve, we can also recommend, design, develop, produce the products according to the drawings and requirements of the customers.