Tungsten Carbide Sealing Ring Factories – Tungsten Carbide Thrust Washer for Pumps – N&D

Short Description:

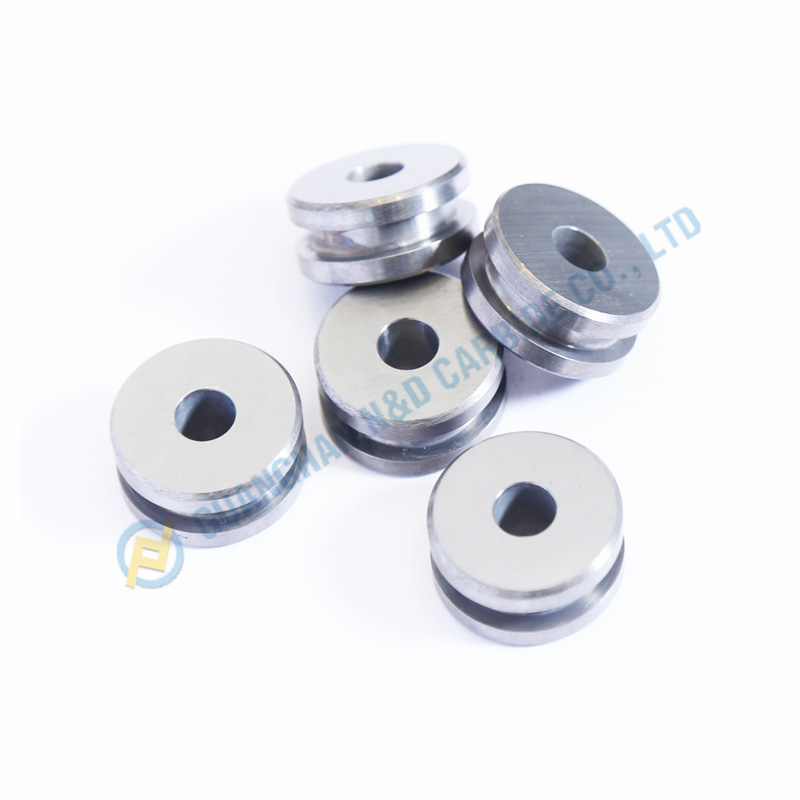

Tungsten Carbide Sealing Ring Factories – Tungsten Carbide Thrust Washer for Pumps – N&D Detail:

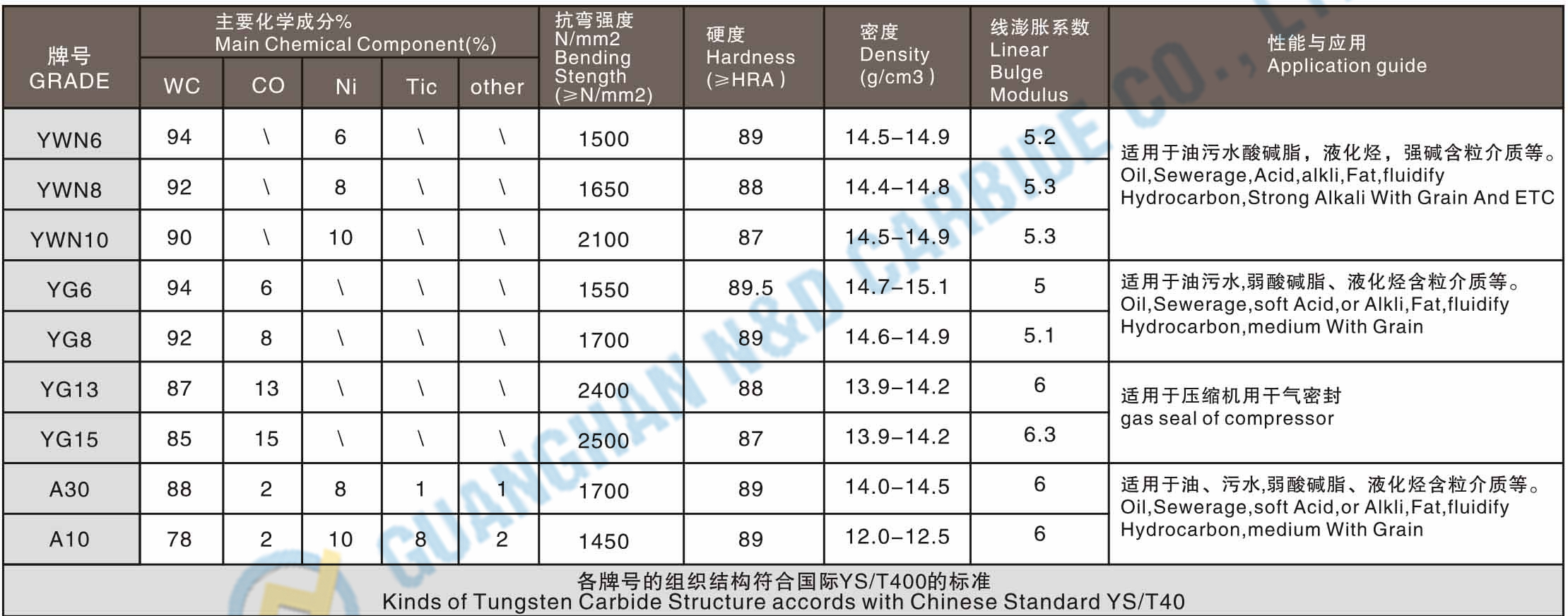

Tungsten Carbide – Cemented tungsten carbides are derived from a high percentage of tungsten carbide particles bonded together by a ductile metal. The common binders used for seal rings are nickel and cobalt. The resultant properties are dependent upon the tungsten matrix and percentage of binder (typically 6 to 15% by weight per volume). Tungsten carbide is an extremely tough material with good wear resistance, with Nickel bound being the most common material used in midstream pipeline applications. Seal rings in this material offer improved protection against mechanical or thermal shock, but will be limited in PV characteristics and are more susceptible to heat checking damage when compared against advanced ceramics.

Tungsten carbide(TC) is widely used as seal faces or rings with resistant-wearing, high fractural strength,high thermal conductivity, small heat expansion co-efficient. The tungsten carbide seal-ring can be divided into both of rotating seal-ring and static seal-ring. The two most common variations of tungsten carbide seal faces/ring are cobalt binder and nickel binder.

ND carbide produces seal rings in several grade types including an entire family of nickel-bonded grades that provide superior corrosion resistance.N&D Carbide’s standard lapped and polished seal faces are flat within 1 helium light bands. ND Carbide manufactures to customer specifications only – you get the exact tolerances, finishes, and carbide grade that your application demands.

Tungsten Carbide thrust washer are widely used for pumps, compressors mixers and agitators found in oil refineries, petrochemical plants, fertilizer plants, breweries, mining , pulp mills, and the pharmaceutical industry.

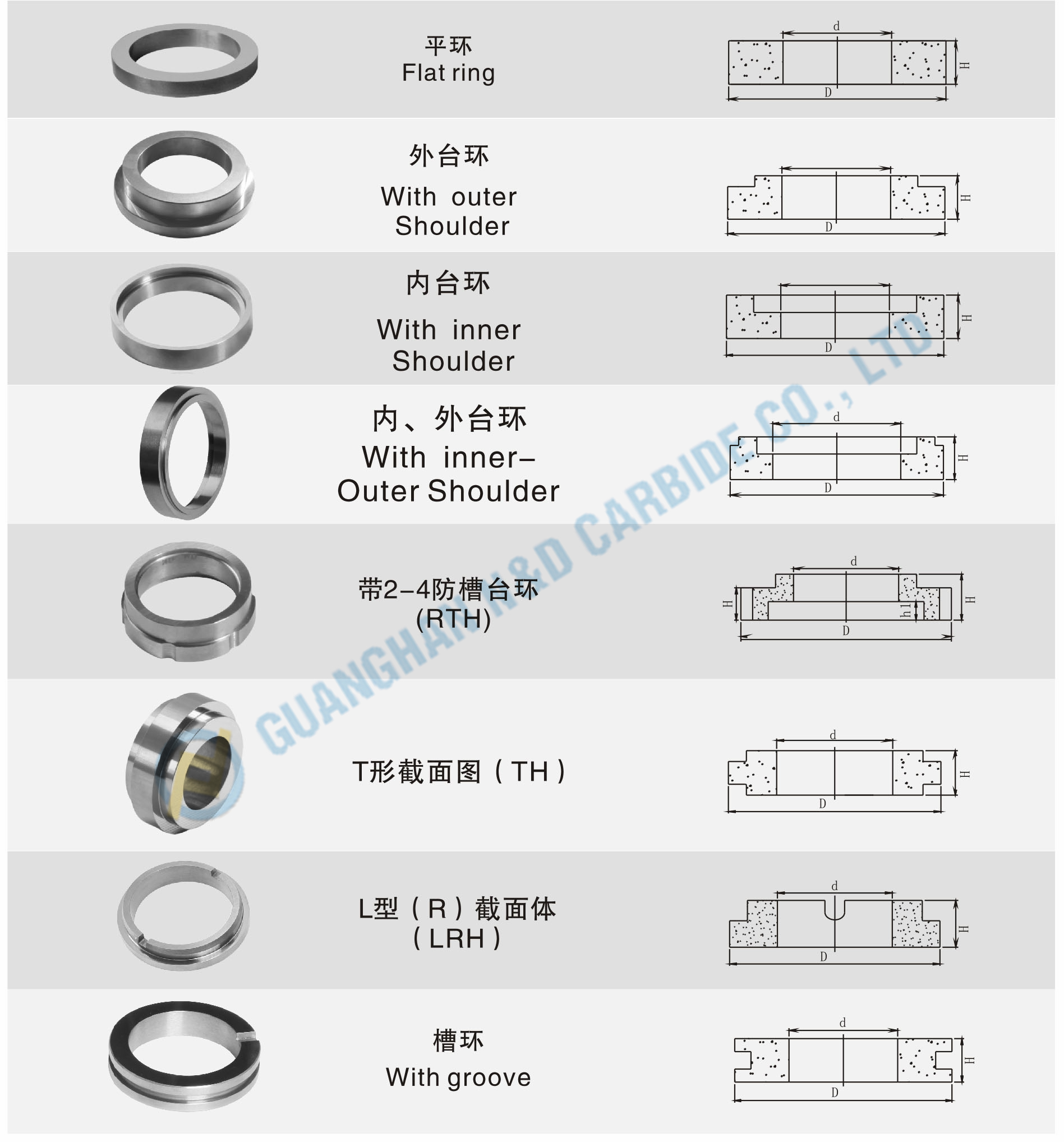

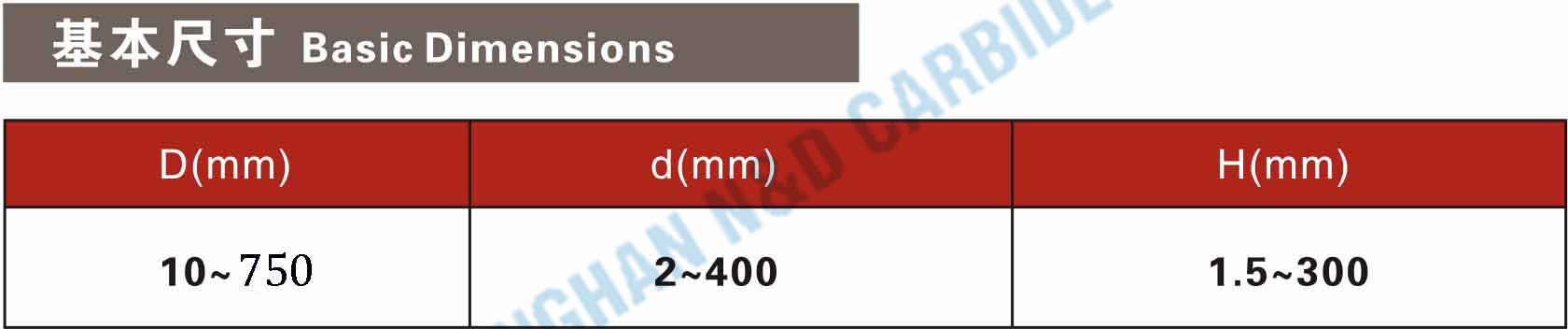

There is a big choice of sizes and types of the tungsten carbide flat seal ring, we can also recommend, design, develop, produce the products according to the drawings and requirements of the customers.

Product detail pictures:

Related Product Guide:

No matter new buyer or old purchaser, We believe in long expression and trusted relationship for Tungsten Carbide Sealing Ring Factories – Tungsten Carbide Thrust Washer for Pumps – N&D, The product will supply to all over the world, such as: Rome, Sri Lanka, Netherlands, We have now a large share in global market. Our company has strong economic strength and offers excellent sale service. Now we have established faith, friendly, harmonious business relationship with customers in different countries. , such as Indonesia, Myanmar, Indi and other Southeast Asian countries and European, African and Latin American countries.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!